Have you ever wondered about the clarity of those X-ray films that doctors use to peek into our bodies? Beyond the skilled hands of radiologists and technologically advanced X-ray machines, there’s a silent hero that plays a significant role – the coating on X-ray film. Let’s dive deep into this unsung hero’s realm and unravel its mystery.

Table of Contents

What is X-ray Film Coating?

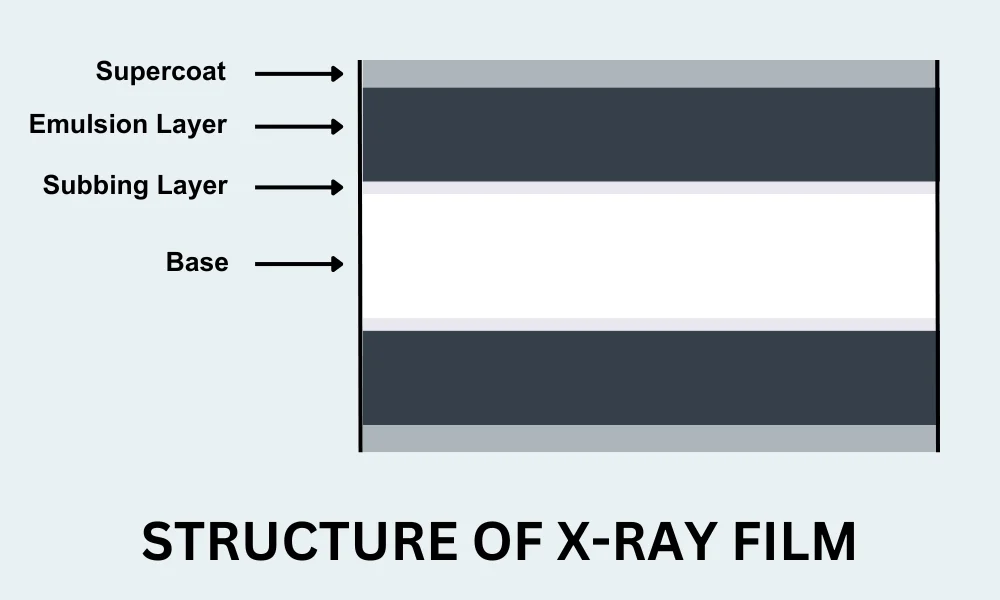

In its essence, medical X-ray film coating isn’t just a protective layer. It’s the canvas where our body paints its story. While the film base provides structural support, the coating, laden with essential components like silver halide crystals, captures and displays the image.

Think of it as a painter’s canvas – the base holds the shape, while the coating ensures the paint (or in this case, the X-ray) shows every detail perfectly.

Components of the Coating

A closer look at the coating feels like gazing into a starlit sky:

- Emulsion: The shining stars here are the silver halide crystals. They are the primary agents capturing the X-ray images. It’s fascinating, isn’t it, how these tiny crystals can hold an image of our very bones?

- Gelatin: Imagine a net holding these stars together. That’s our binder – the gelatin. It ensures that everything stays in place, providing a medium for the crystals.

- Other additives: Like a pinch of magic, additives like hardeners increase the film’s durability, wetting agents ensure a smooth coating process, and stabilizers make sure the film has a longer shelf life.

Why Coat X-ray Films?

Ever wondered why not all papers are suitable for watercolor? Similarly, the coating on X-ray films determines the sensitivity, protection, and stability of the image.

- Sensitivity: With proper coating, the film can capture even the subtlest of details, ensuring accurate diagnostics.

- Protection: Just as we wear jackets in the rain, the X-ray film needs protection too, especially from physical damage and harmful environmental factors.

- Stability: What’s the point if memories fade away? Similarly, a good coating ensures that the images don’t degrade over time, retaining their clarity for years.

The Step-by-Step Process: Coating on X-ray Film

- Picture this: a piece of film going through a transformative journey, much like a caterpillar turning into a butterfly.

- Preparing the base: It starts with ensuring the base is pristine – free from dust or impurities. It’s like preparing a blank canvas for a masterpiece.

- Mixing the emulsion: The magic potion! Ingredients are mixed meticulously to ensure uniformity. It’s almost as if brewing the perfect cup of coffee.

- Application: Different methods, be it dip-coating, curtain-coating, or extrusion, are like the brushes of an artist, each giving a unique finish.

- Drying and curing: The masterpiece is almost complete. It’s now left to set, solidifying the emulsion, and ensuring its durability.

Quality Control in the Coating Process

Perfection is the goal. And to achieve it:

- Uniformity: Like ensuring every note in a symphony is perfect, the coating thickness must be consistent.

- Testing: Films undergo rigorous tests. If a painting is blotchy, would you buy it? Similarly, any deviation from standards, and the batch is re-evaluated.

- Addressing issues: If there’s a hiccup, it’s back to the drawing board. After all, there’s no compromise when it comes to health.

Innovations in X-ray Film Coating

From traditional hand-drawn maps to Google Maps, evolution is inevitable. Digital X-ray films are making an entrance, but the essence of the coating remains. The pursuit? Always better, clearer, and more reliable imaging for the future.

Conclusion

As we pull the curtain down on our behind-the-scenes tour, let’s take a moment to appreciate the art and science behind each X-ray film. Next time you see one, remember the intricate dance of components and processes that make it possible to see the unseen.

FAQ

Q1: How long does the coating process typically take for X-ray films?

Answer: Depending on the method and the specific requirements, it can take anywhere from a few hours to a couple of days.

Q2: Why are silver halide crystals crucial in X-ray film coating?

Answer: These tiny crystals are the primary agents that react to X-rays and capture the image. It’s their interaction that allows us to see the images.

Q3: Can defects in the coating process affect the diagnostic capability of the film?

Answer: Absolutely! Imperfections can lead to unclear images or artifacts, making diagnosis challenging.

Q4: Are there environmental concerns associated with X-ray film coating?

Answer: As with many manufacturing processes, there can be environmental impacts. However, the industry has made significant strides in minimizing these through sustainable practices and waste management.