Have you ever considered the meticulous craftsmanship behind the scenes of healthcare printing? Maintaining the accuracy and integrity of patient records is crucial in healthcare. Medical printing plays a significant role in ensuring that all patient data, including images and reports, are accurately recorded and stored. Quality control in medical printing is essential to preserve precision and reliability. This blog post explores the importance of quality control in medical printing, best practices, and its impact on patient care.

Table of Contents

Understanding Medical Printing

What Is Medical Printing?

Medical printing involves producing hard copies of various medical records, including patient charts, diagnostic images, lab reports, and prescriptions. These printed documents are vital for patient care, as they provide healthcare professionals with the necessary information to diagnose and treat patients effectively.

Importance of Accuracy in Medical Printing

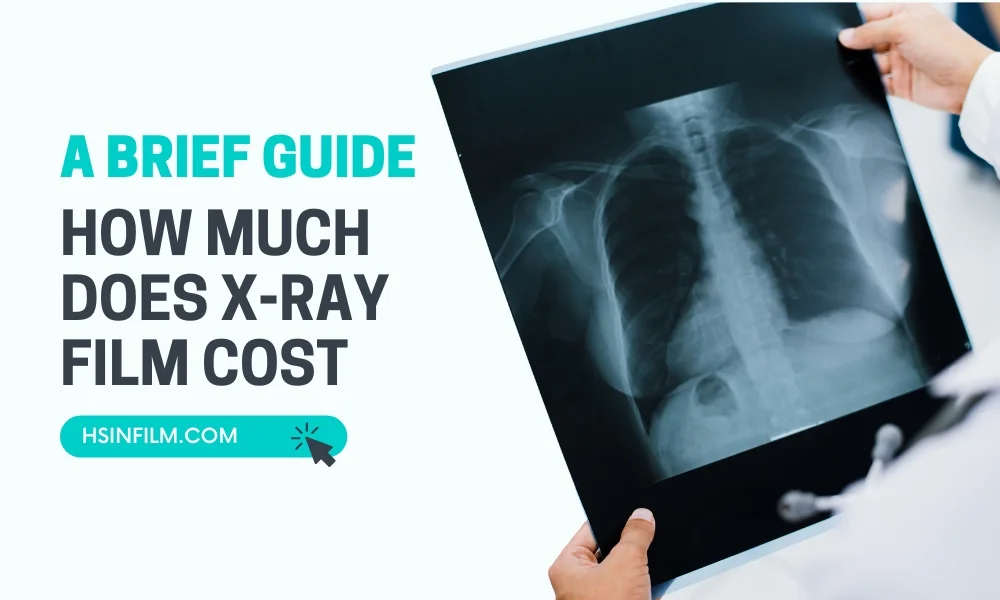

Accuracy in medical printing is paramount because even a minor error can lead to significant consequences. Inaccurate records can result in misdiagnoses, inappropriate treatments, and delays in patient care. Therefore, maintaining precision in medical printing is critical for ensuring patient safety and effective healthcare delivery.

The Significance of Quality Control in Healthcare Printing

Imagine a healthcare document as a musical score, each note representing vital patient information. Just as a wrong note can disrupt a beautiful melody, an error in a medical record can have severe consequences. We’ll begin by understanding the profound significance of quality control in healthcare printing. Errors in patient records can lead to inaccurate diagnoses, incorrect treatments, and a detrimental impact on patient safety.

Ensuring Accuracy and Reliability

Quality control processes in medical printing are designed to ensure that all printed materials are accurate and reliable. This involves checking for errors, verifying information, and ensuring that all printed documents meet the required standards.

Maintaining Consistency

Consistency is crucial in medical printing. Quality control helps maintain consistency in the appearance and format of printed documents, which is important for easy reading and interpretation by healthcare professionals. Consistent formatting also ensures that documents are easily identifiable and accessible when needed.

Color Management

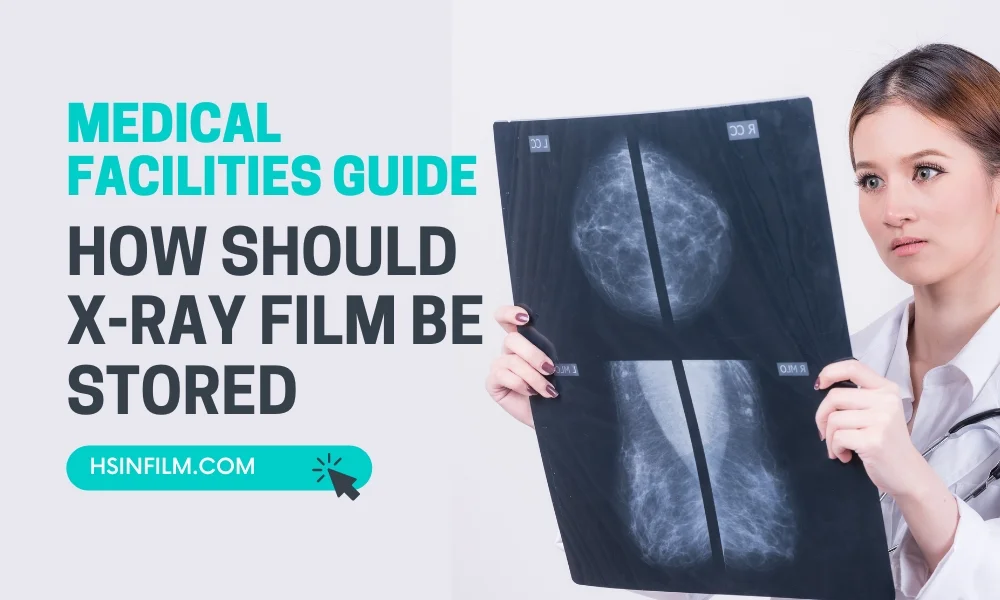

Color in healthcare documents can be likened to the palette of a painter. Accurate color representation is vital, especially in medical images and records. We’ll delve into the role of color management in maintaining the fidelity of medical prints.

Data Integrity and Security

Patient information is the heart of medical records, and its integrity is sacrosanct. The healthcare industry prioritizes data integrity and security. We’ll discuss the measures and safeguards in place to protect patient information and maintain confidentiality.

Print Verification and Validation

A musician may rehearse and fine-tune their performance, and medical printing follows a similar principle. Print verification and validation processes ensure that every document is flawless. We’ll explore these procedures, including the use of test prints and reference materials to confirm accuracy.

Preventing Errors

Errors in medical printing can have serious implications for patient care. Quality control measures help prevent errors by implementing checks and balances at various stages of the printing process. This includes verifying patient information, checking print quality, and ensuring that all data is accurately captured.

Human Oversight

Just as an orchestra requires the skill and expertise of its musicians, healthcare printing relies on human oversight. Healthcare professionals play a vital role in ensuring accuracy during the printing process. We’ll delve into their responsibilities and contributions to quality control.

Best Practices for Quality Control in Medical Printing

Implementing Standard Operating Procedures (SOPs)

Standard Operating Procedures (SOPs) provide a clear and consistent framework for medical printing processes. SOPs outline the steps and protocols that must be followed to ensure accuracy and reliability. Implementing SOPs helps maintain high standards and reduces the risk of errors.

Regular Equipment Maintenance

Regular maintenance of printing equipment is essential for ensuring print quality and preventing malfunctions. Regular checks and servicing of printers, copiers, and other printing devices help maintain their efficiency and accuracy. Well-maintained equipment produces high-quality prints and reduces the risk of errors.

Training Staff

Properly trained staff are crucial for maintaining quality control in medical printing. Training programs should be implemented to ensure that all staff members are familiar with the printing processes, quality control measures, and the importance of accuracy. Continuous training helps staff stay updated on best practices and new technologies.

Implementing Double-Check Systems

Double-check systems involve having two or more individuals verify the accuracy of printed documents. This additional layer of verification helps catch errors that may have been missed during the initial printing process. Double-check systems are especially important for critical documents, such as diagnostic reports and prescriptions.

Using High-Quality Printing Materials

Using high-quality paper, ink, and other printing materials is essential for ensuring print clarity and durability. High-quality materials produce clearer images and text, which are easier to read and interpret. Additionally, durable materials ensure that printed documents remain intact and legible over time.

Digital Integration

Integrating digital systems with medical printing processes can enhance accuracy and efficiency. Digital systems allow for easy storage, retrieval, and sharing of patient records. They also enable automated quality control checks, reducing the risk of human error.

Impact of Quality Control on Patient Care

Improving Diagnosis and Treatment

Accurate and reliable printed records are essential for effective diagnosis and treatment. Quality control ensures that all patient information, including diagnostic images and lab reports, is accurately captured and printed. This helps healthcare professionals make informed decisions and provide appropriate treatments.

Enhancing Patient Safety

Quality control measures help prevent errors that could compromise patient safety. By ensuring that all printed documents are accurate and reliable, quality control reduces the risk of misdiagnoses, incorrect treatments, and other adverse outcomes.

Streamlining Workflow

Efficient quality control processes streamline the workflow in healthcare facilities. Accurate and consistent printed documents are easier to read and interpret, reducing the time spent on verifying information. This allows healthcare professionals to focus more on patient care and less on administrative tasks.

Ensuring Compliance

Healthcare facilities must comply with various regulations and standards related to patient records. Quality control helps ensure that all printed documents meet the required standards and comply with regulations. This reduces the risk of legal issues and enhances the credibility of the healthcare facility.

Challenges in Quality Control for Medical Printing

Keeping Up with Technological Advancements

The rapid pace of technological advancements in medical printing presents a challenge for quality control. Healthcare facilities must continually update their equipment and processes to keep up with new technologies. Staying updated with the latest advancements helps maintain high standards and improve accuracy.

Managing High Volumes of Print

Healthcare facilities often deal with high volumes of printed documents. Managing this volume while maintaining accuracy and reliability can be challenging. Implementing efficient quality control processes and using automated systems can help manage high print volumes effectively.

Ensuring Staff Competency

Ensuring that all staff members are competent and well-trained in quality control processes is essential. This requires continuous training and monitoring to ensure that staff members are familiar with best practices and new technologies. Investing in staff training helps maintain high standards and improve accuracy.

Balancing Cost and Quality

Balancing cost and quality is a common challenge in medical printing. While high-quality printing materials and equipment may be more expensive, they are essential for ensuring accuracy and reliability. Healthcare facilities must find a balance between cost and quality to maintain high standards without overspending.

Conclusion

Quality control in medical printing is essential for preserving precision in patient records and ensuring effective patient care. Implementing best practices, such as standard operating procedures, regular equipment maintenance, staff training, double-checking systems, and using high-quality materials, helps maintain accuracy and reliability. Quality control measures improve diagnosis and treatment, enhance patient safety, streamline workflow, and ensure compliance with regulations. While there are challenges in maintaining quality control, advancements in automation, AI, and digital transformation are expected to enhance the process further. By prioritizing quality control in medical printing, healthcare facilities can ensure that patient records are accurate reliable, and effectively support patient care.