Isn’t it fascinating how medical technology continues to evolve, making diagnosis more accurate and treatments more effective? One such revolutionary stride is the enhancement of medical imaging with thermal film. Before we dive into the intricacies of this topic, let’s take a step back. Can you imagine a time when physicians had to solely rely on symptoms and physical examinations? Fast forward to today, and diagnostic imaging has fundamentally transformed patient care. But how exactly does thermal film play into this transformation?

Table of Contents

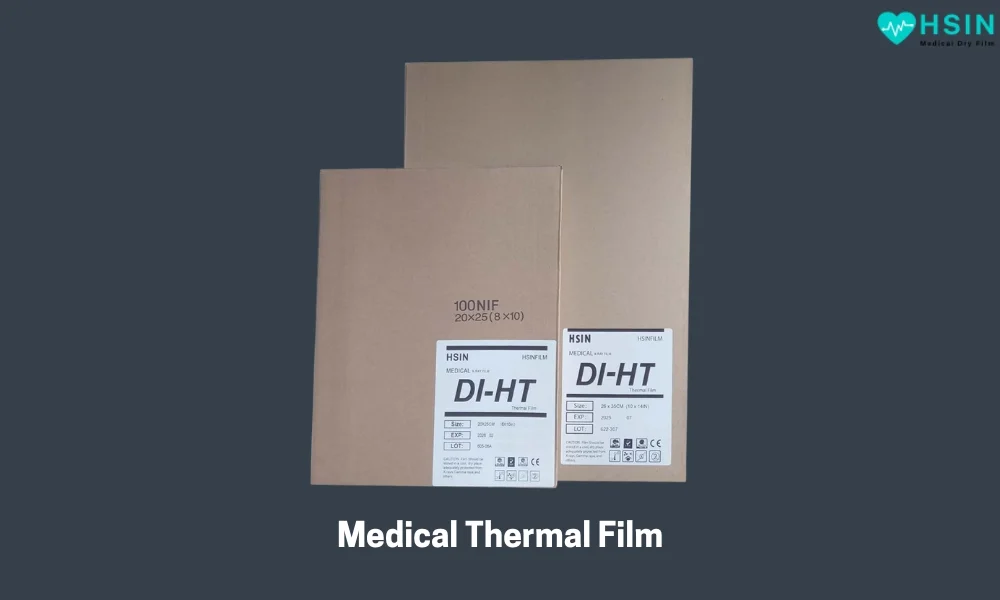

What is Medical Thermal Film?

Medical Thermal Film, often shrouded in mystery for those outside the medical field, is simply a specialized type of film used for diagnostic purposes. While it shares certain characteristics with the thermal film we might find in everyday printing applications, it’s specifically crafted for the healthcare sector. So, why all the buzz about enhancing medical imaging with thermal film?

Why Medical Thermal Film Matters in Diagnostics

Let’s paint a picture. Imagine trying to read a book, but the words are blurry. Frustrating, isn’t it? That’s what medical imaging can be like without the clarity and precision thermal film offers. By enhancing medical imaging, it directly contributes to:

- Improved diagnostic accuracy.

- Faster diagnosis, leading to timely treatments.

- Reduced chances of medical errors.

How Medical Thermal Film Works

Ever wondered about the magic behind the scenes? It’s a blend of science and technology. The film is sensitive to heat, and when exposed to a thermal print head, it produces a high-resolution image. Unlike traditional films which relied on chemicals and a darkroom, the thermal process is direct and rapid. But how does this compare with other imaging techniques?

Advantages of Using Medical Thermal Film

Let’s lay down the facts in a snapshot:

- High-resolution Imaging: Capture even the minutest of details.

- Durability: Unlike traditional films, these are less prone to wear and tear.

- Swift Processing Times: In the world of medicine, every second counts!

- Cost-effective: In the long run, the investment pays off when compared to other methods.

Are these benefits exclusive to all medical disciplines? Let’s explore.

Applications in Different Medical Disciplines

From examining a sprained ankle to detecting a dental cavity, the applications of enhancing medical imaging with thermal film are vast. Some common uses include:

- Radiology: Whether it’s an X-ray, MRI, or CT scan, the clarity is unparalleled.

- Ultrasound Imaging: Ever seen those heartwarming first images of a baby? Thank thermal film for the clarity!

- Dental Imaging: Spotting cavities and other dental issues have never been clearer.

Integration with Modern Medical Equipment

Tech geeks, rejoice! The medical thermal film is compatible with an array of modern imaging machinery. Manufacturers are continually innovating to ensure seamless integration, making the diagnostic process smoother and more efficient.

Storage, Safety, and Maintenance

Like any valuable item, medical thermal films need love and care. Store them in cool, dry places, away from direct sunlight. And when it comes to disposal? Always follow health and environmental safety protocols to ensure our planet stays green and clean.

Challenges and Limitations

Is thermal film the silver bullet for all medical imaging needs? While it’s a game-changer, there are situations where other methods might be more suitable. But with ongoing advancements, who knows what the future holds?

The Future of Medical Imaging with Thermal Film

Speaking of the future, the horizon looks bright. As technology and medicine continue to intertwine, the potential for enhancing medical imaging with thermal film is boundless. We can expect sharper images, faster processing, and even more applications.

Conclusion

In the ever-evolving landscape of healthcare, one thing remains constant: the quest for better patient care. And by enhancing medical imaging with thermal film, we are one step closer to that goal.

FAQs

Q: Is medical thermal film safe for all types of patients?

A: Absolutely! It’s just a medium for capturing images and does not expose patients to any risks.

Q: How does the cost of thermal film imaging compare with digital methods?

A: While the initial setup might be pricier, in the long run, it proves to be cost-effective due to its durability and efficiency.

Q: What are the environmental implications of using and discarding medical thermal films?

A: Proper disposal methods ensure minimal environmental impact. Always adhere to recommended guidelines to maintain sustainability.