In our fast-evolving healthcare landscape, the tools and technologies we use can make a significant difference in patient outcomes. One such tool that often flies under the radar but plays a pivotal role in patient care is the medical thermal printer. But what exactly is the role of medical thermal printers in healthcare, and why is it crucial?

Table of Contents: Role of Medical Thermal Printers

Introduction

Ever pondered how advancements in the field of printing have revolutionized healthcare? The journey has been quite fascinating. Gone are the days of tedious manual documentation. Today, we have medical thermal printers that provide clarity, speed, and efficiency like never before. Isn’t it curious how a machine can transform an industry?

Understanding Medical Thermal Printers

At its core, a medical thermal printer employs heat to produce images or text on paper. Simple, yet ingenious.

- Definition: It’s a device that uses heat-sensitive paper and a heated printhead to produce high-quality images or text.

- Types:

- Direct Thermal Printing: Directly heats the paper to produce images. Perfect for short-lived prints like receipts.

- Thermal Transfer Printing: Uses heat to transfer ink from a ribbon to paper. Ideal for longer-lasting prints.

Significance in Healthcare

Ever thought about why healthcare setups prefer medical thermal printers over standard printers? Here’s a glimpse:

- Speed: In emergencies, every second counts. Quick prints can make all the difference.

- Clarity: Precision is non-negotiable when patient lives hang in the balance.

- Reliability: Because malfunctions in healthcare can cost lives.

Key Applications in Healthcare

Medical thermal printers aren’t just restricted to one function. Their adaptability and efficiency have paved the way for a myriad of applications.

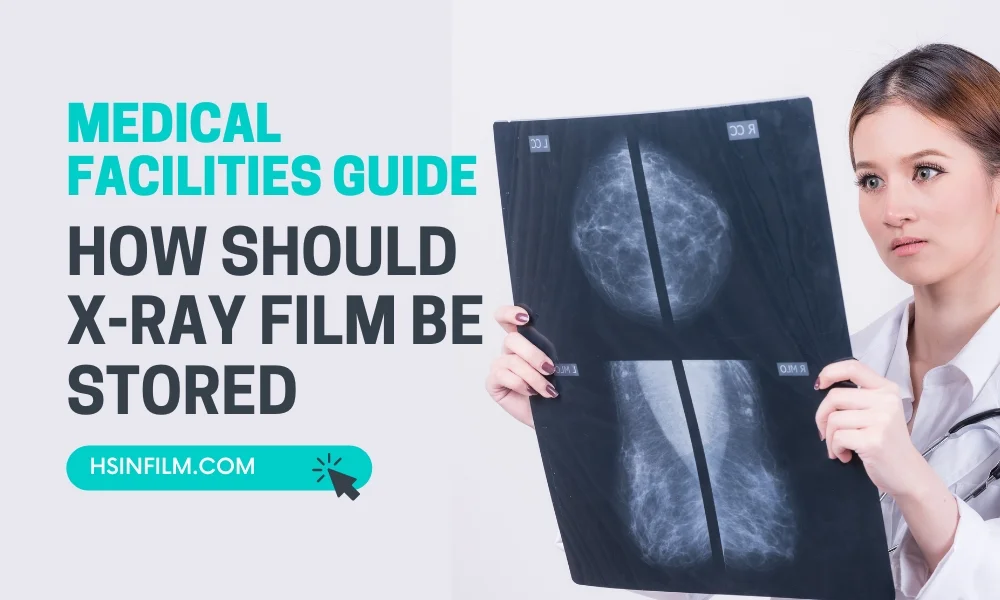

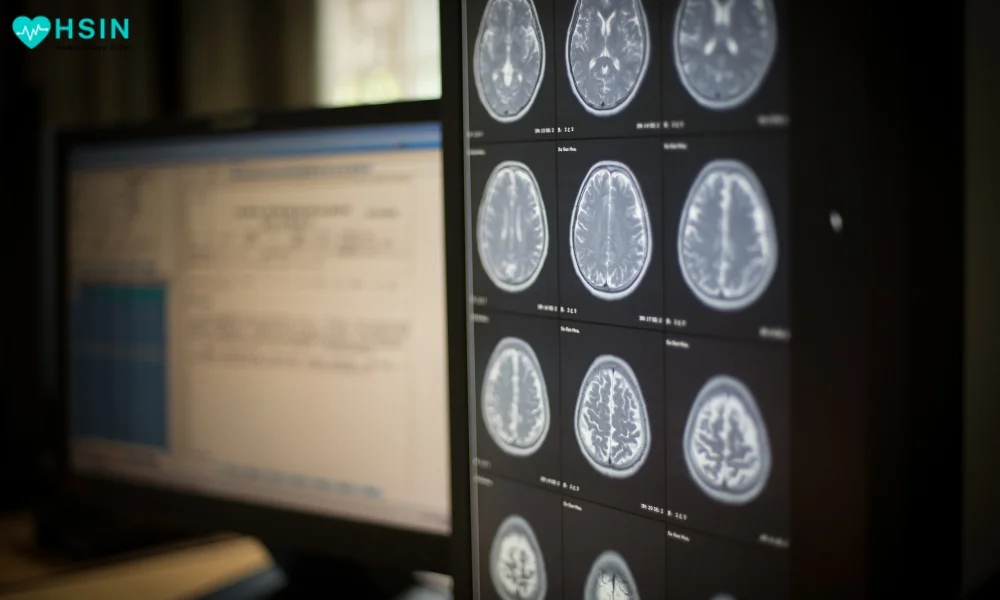

- Medical Imaging: A clear ultrasound, MRI, or CT scan print can aid in accurate diagnoses.

- Barcode Printing: Patient identification, and medication tracking—all streamlined.

- Reports: Instantaneously printing patient reports ensures swift action.

- Laboratory Use: Imagine every sample labeled with precision and clarity.

Advantages of Medical Thermal Printers

Why are these printers the unsung heroes of healthcare?

- Speed: Time is of the essence in healthcare. Rapid image and report generation can be life-saving.

- Durability: These prints withstand the test of time—and external factors!

- Cost-Effective: While initial costs may be high, their longevity and low maintenance make them cost-effective.

- Clarity and Precision: When it comes to medical images, there’s no room for error.

Challenges and Considerations

No technology is devoid of challenges, and understanding them can lead to better utilization.

- Maintenance: Regular upkeep ensures the longevity of the machine.

- Quality Consumables: For the best output, using high-quality consumables is a must.

- Environmental Concerns: How do we dispose of used materials? An eco-conscious approach is vital.

Innovation and Future Trends

Medical thermal printers have come a long way, but where are they headed next?

- EHR Integration: Imagine printers seamlessly connected to Electronic Health Records.

- Eco-Friendly Designs: With the rise in environmental consciousness, future models may prioritize sustainability.

- Compactness: For remote healthcare setups, smaller, portable designs might be the way forward.

Conclusion

The role of medical thermal printers in healthcare is undeniable. Its transformative impact, from enhancing diagnostics to improving patient care, is a testament to its indispensable nature. And as technology evolves, it’s exciting to envision its promising future!

FAQs

Q: What’s the primary difference between direct thermal printing and thermal transfer printing?

A: Direct thermal printing uses heat-sensitive paper, whereas thermal transfer uses a ribbon and regular paper.

Q: Are medical thermal prints long-lasting?

A: While direct thermal prints may fade over time, thermal transfer prints are designed for longevity.

Q: Can these printers integrate with hospital management systems?

A: Absolutely! Many modern models offer seamless integration with various management and record systems.

This journey into the world of medical thermal printers illustrates their understated but monumental role in healthcare. It makes one wonder, doesn’t it? What other unnoticed technologies serve as the backbone of modern healthcare?