Ever wondered how the intricacies of the human body are captured with impeccable clarity in medical images? Behind every clear diagnostic image, there’s an unsung hero: the medical thermal printer. With a relentless surge in the need for precise diagnostic imaging, understanding the role of these printers becomes imperative. Let’s embark on this insightful journey to see how medical thermal printers enhance diagnostic imaging.

Table of Contents: Medical Thermal Printers Enhance Diagnostic Imaging

What are Medical Thermal Printers?

Thermal printing, at its core, utilizes heat to produce an image on paper. But medical thermal printers aren’t your run-of-the-mill thermal printers.

- Definition: Medical thermal printers specifically cater to the healthcare sector’s demand for high-quality images.

- Distinct Feature: Unlike standard printers, these are calibrated for medical precision, ensuring images are not just clear but accurate for diagnoses.

Isn’t it fascinating that a simple heat application can lead to such diagnostic clarity?

The Science Behind Thermal Printing

Heat and paper – that’s all it takes. But how?

- Thermal Heads: These are the magic wands. They generate heat patterns to create images.

- Thermal Paper: A special chemically treated paper that darkens upon heating, capturing the finest details.

Think of it as an intricate dance of heat, where every step is a pixel ensuring clarity. But how does this process stand out?

Advantages of Using Medical Thermal Printers in Diagnostic Imaging

In the healthcare maze, accuracy isn’t just preferred – it’s imperative.

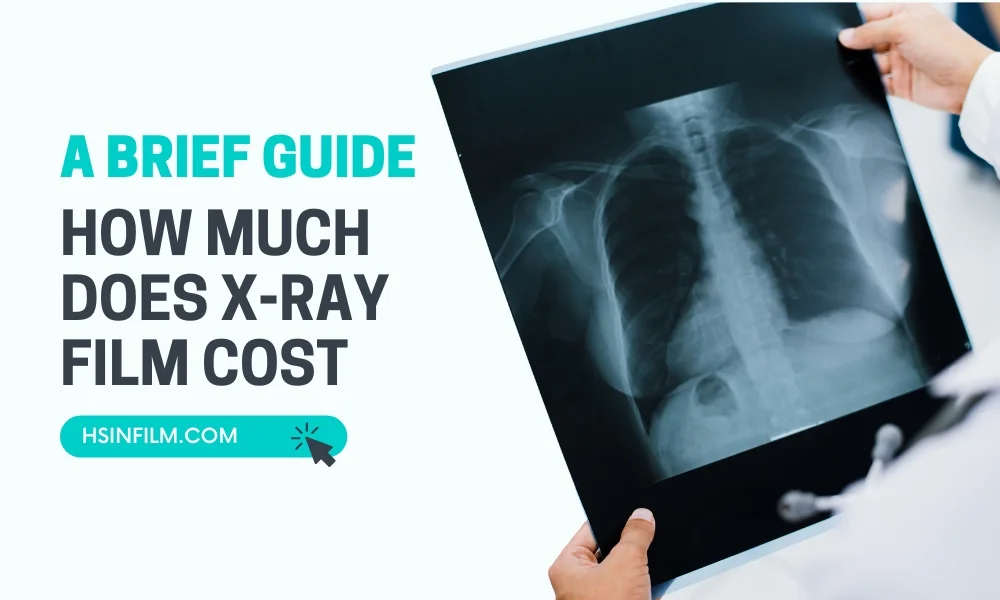

- High-resolution prints: Ever stared at a blurry image, wondering if it’s a bird or a plane? In diagnostics, that clarity can be life-saving.

- Quick printing speeds: In medical emergencies, every second counts. Fast printouts ensure timely decisions.

- Durability: Like age-old wisdom, these prints stand the test of time, crucial for longitudinal studies and patient histories.

- Consistency: Whether it’s the first or the fiftieth print, the quality remains uncompromised.

Comparison with Other Medical Printing Technologies

In the battle of the printers, how does thermal fare?

- Inkjet vs. thermal: While inkjets spray ink on paper, thermal printers provide clearer images without the risk of smudges. Can you imagine the implications of a misinterpreted smudge on a lung X-ray?

Consistency, clarity, and quick outputs make thermal printing the knight in shining armor in the medical world.

Real-world Applications of Medical Thermal Printing in Healthcare

Picture this: a busy radiology department inundated with patients. The transition to thermal printing not only streamlined their workflow but also enhanced image clarity. Result? Faster, accurate diagnoses and a surge in patient trust.

Future Prospects of Thermal Printing in Medical Imaging

With digital health making waves, where does thermal printing stand?

The horizon looks promising! As telemedicine grows, the demand for clear remote diagnostic images will skyrocket, placing thermal printing right at the epicenter of this revolution.

Conclusion

In the realm of healthcare, where precision meets passion, medical thermal printers have carved a niche for themselves, ensuring that diagnostic imaging remains clear, accurate, and effective. So, the next time you come across a medical image, remember the silent enabler behind it.

FAQ

Q: Can medical thermal printers be used for all types of diagnostic images?

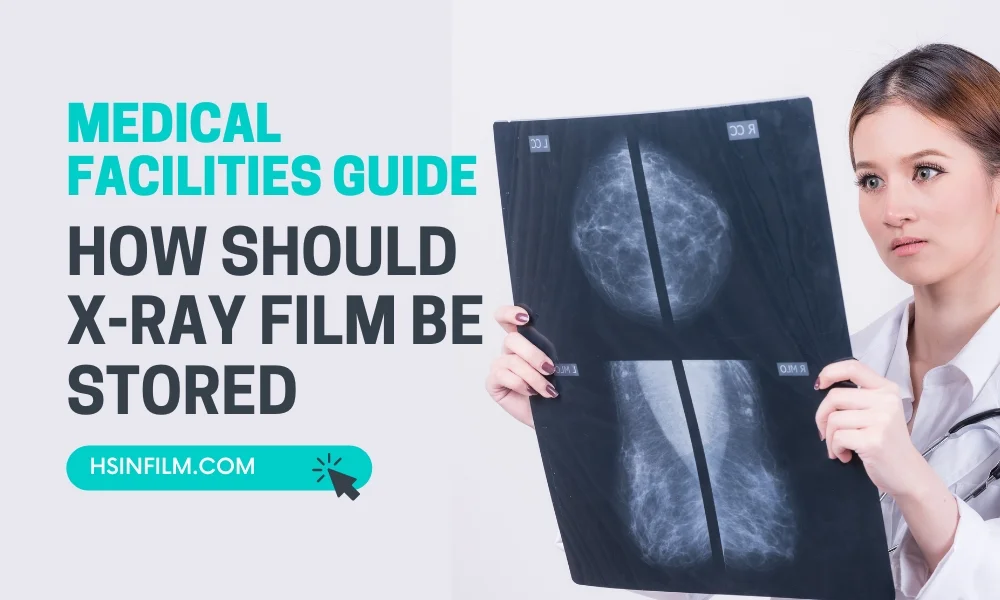

A: Absolutely! From X-rays to ultrasound images, they cater to a broad spectrum.

Q: How long do these thermal prints last?

A: With proper care, they can last for years, making them ideal for medical records.

Q: Are these printers cost-effective compared to others?

A: While the initial investment might be higher, their durability and precision make them cost-effective in the long run.

References

- Comparative Analysis: Inkjet vs. Thermal Printing in Healthcare

- The Future of Diagnostic Imaging: A Comprehensive Study

With this, we wrap up our deep dive into the world of medical thermal printing. Here’s to clearer images and sharper diagnoses! 🩺🖨️